Contact Us 1300 135 140

If you have any questions about testing periods, you can call us any time.

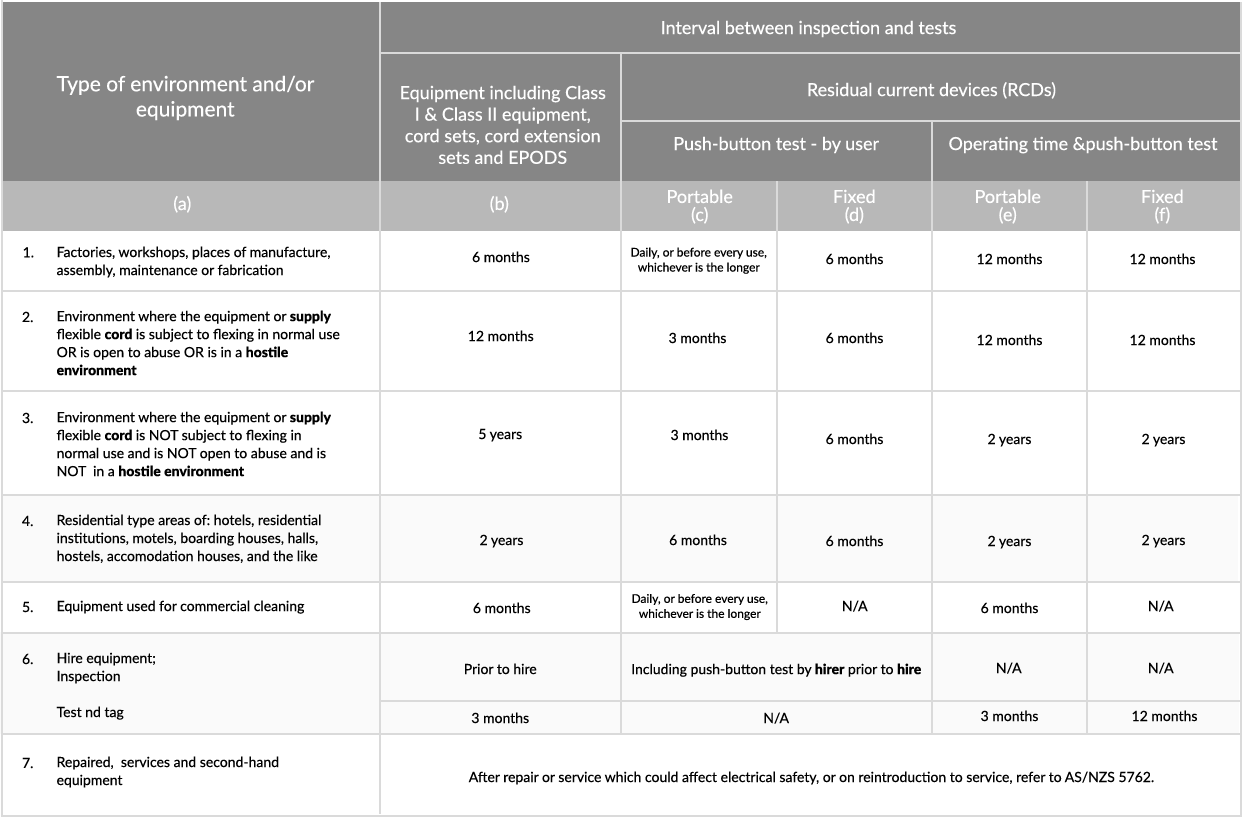

Test Period as outlined in the standard - AS/NZS 3760:2010

Useful Definitions from AS/NZS 3760:2010

One in which the equipment or appliance is normally subject to events or operating conditions likely to result in damage to the equipment or a reduction in its expected life span. This includes, but is not limited to mechanical damage, exposure to moisture, heat, vibration, corrosive chemicals, and dust.

A mechanical switching device designed to make, carry and break currents under normal service conditions, and to cause the opening of the contacts when the residual current attains a given value under specified conditions. The RCD may be fixed or portable (PRCD).

Electrical equipment shall be inspected and tested: (a) At intervals indicated in Table 4 (subject to a tolerance of two weeks), or as varied by a responsible person based on a risk assessment;

NOTE –

(1) Regulatory authorities, other Standards, workplace safety requirements or manufacturers’ instructions may specify shorter or longer intervals appropriate to particular industries or specific types of equipment.

(2) Some regulatory jurisdictions limit the inspection and testing of electrical equipment to defined work activity or working environment s. For example construction wok or equipment used in a hostile operating environment.

(b) On return to service after a repair or servicing, that could have affected the electrical safety of the equipment. AS/NZS 5762 may apply;

(c) Before placement in service, if sourced from a second-hand sale, to ensure the equipment is safe. AS/NZS 5761 shall apply.

This is how some of our clients feels after working with us.

Putting our trust in Asset Test & Tag has allowed us to run our business confidently in the knowledge that we are always complaint. Their diligent service and flexibility makes it all too easy.

Hallmark Commercial

We have been using Asset Test & Tag for more than five years. They are a local South Australian business where John and his team always deliver quality service and a great customer experience.

Manager, Corporate Services

Asset Test and Tag has made compliance with testing easy. Where we used to worry that tools and machinery were compliant, now don’t even think about it. It’s like it just happens in the background. No worries, no inconvenience and fully compliant. It’s a no brainer. Thanks John and team

Director Comace

When our Test and Tag fell through, they came to our rescue. John rearranged his schedule so he could fit us in and get us compliant before our Accreditation Day. I’m so grateful for their help and high level of service.

Pharmacist

Great communication, reliable efficient service. I highly recommend Asset Test and Tag!

C & E Stainless Steel

Emergency and Exit Lighting requires testing every 6 months

This is how some of our clients feels after working with us.

Putting our trust in Asset Test & Tag has allowed us to run our business confidently in the knowledge that we are always complaint. Their diligent service and flexibility makes it all too easy.

Hallmark Commercial

We have been using Asset Test & Tag for more than five years. They are a local South Australian business where John and his team always deliver quality service and a great customer experience.

Manager, Corporate Services

Asset Test and Tag has made compliance with testing easy. Where we used to worry that tools and machinery were compliant, now don’t even think about it. It’s like it just happens in the background. No worries, no inconvenience and fully compliant. It’s a no brainer. Thanks John and team

Director Comace

When our Test and Tag fell through, they came to our rescue. John rearranged his schedule so he could fit us in and get us compliant before our Accreditation Day. I’m so grateful for their help and high level of service.

Pharmacist

Great communication, reliable efficient service. I highly recommend Asset Test and Tag!

C & E Stainless Steel

Fire Extinguisher and Fire Blanket requires testing every 6 months

Extracted from the standard AS 1851-2012 Routine service of fire protection systems and equipment

This is how some of our clients feels after working with us.

Putting our trust in Asset Test & Tag has allowed us to run our business confidently in the knowledge that we are always complaint. Their diligent service and flexibility makes it all too easy.

Hallmark Commercial

We have been using Asset Test & Tag for more than five years. They are a local South Australian business where John and his team always deliver quality service and a great customer experience.

Manager, Corporate Services

Asset Test and Tag has made compliance with testing easy. Where we used to worry that tools and machinery were compliant, now don’t even think about it. It’s like it just happens in the background. No worries, no inconvenience and fully compliant. It’s a no brainer. Thanks John and team

Director Comace

When our Test and Tag fell through, they came to our rescue. John rearranged his schedule so he could fit us in and get us compliant before our Accreditation Day. I’m so grateful for their help and high level of service.

Pharmacist

Great communication, reliable efficient service. I highly recommend Asset Test and Tag!

C & E Stainless Steel